What Is Shot Blasting?

As shot blasting goes hand-in-hand with our other services, this part of our business has become something we do in addition to warehouse line painting. And since surface preparation is almost always overlooked when people have their lines painted, we wanted to explain as much as we could about the process.

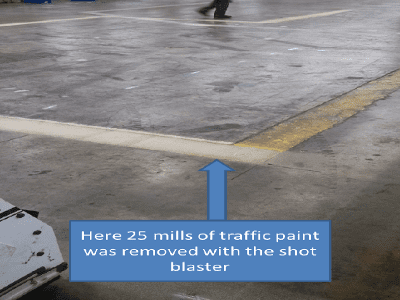

Shot blasting is the process of removing laitance, a weak top layer of cement, from the concrete’s surface. Shot blasting concrete also removes sealers and other thin coatings.

Shot blasting is a preferred method for preparing concrete surfaces that have residue substances including, but not limited to, the following:

- Dirt

- Oil

- Grease

- Curing compounds

- Sealers

- Paint

- Rubbers from tires

The shot blasting process is imperative to get proper adhesion for almost any cement coating. However, we do not always shot blast before striping but always let the customer know that it is important for adhesion.

The Advantages of Shot Blasting Concrete Over Other Processes

Shot blasting is the ideal method of concrete preparation since it both cleans and profiles the floor you’re working on at the same time. Coatings can be applied directly after this industrial blasting service is complete, unlike water blasting or grinding with water attachments.

Additionally, our equipment is very efficient and can execute larger square foot areas while simultaneously collecting any dust made during the process.

Benefits of Choosing Our Concrete Shot Blasting Contractors

Once you’ve decided on the shot blasting process for your surface, our team of professionals can guide you through our procedures, as well as the key benefits that can come when you choose to work with ProMark Contracting.

Some of the benefits you’ll reap when you choose our shot blasting service include:

- No need for the use of toxic chemicals

- High production without dust

- Preparation up to 3,000 square feet per hour

- Ability to have services performed indoors or outdoor

- Ability to have services performed on a variety of surfaces (e.g., parking garages, airport runways)

- The coatings can be applied right after shot blasting is completed

Industry Guidelines for Creating Surface Profiles

The International Concrete Repair Institute (ICRI) has created a technical guideline for shot blasting, #03732. It reads: “Selecting and specifying concrete surface preparation for sealers, coatings, and polymer overlays.”

This guideline provides concrete surface profiles of CSP 3 to 9 which are used by concrete shot blasting contractors under the following conditions:

- Light Shotblast – For coating applications from 4–5 mils in thickness, the surface profile shall be a CSP 3.

- Medium Shotblast – For coating applications from 15–50 mils in thickness, the surface profile shall be a CSP 4 or 5.

- Medium-Heavy Shotblast – For coating applications from 40 mils to 1/8″ in thickness, the surface profile shall be a CSP 5 or 6.

- Heavy Shotblast – For topping applications from 1/4” to 1/2,” the surface profile shall be a CSP 6 or 7.

- Extreme Shotblast – For concrete overlays greater than 1/2,” the surface profile shall be a CSP 8 or 9.

A Recent Project for Our Shot Blasting Services

We were contacted to remove the gray coating (epoxy) at the public pool bathrooms in the City of Rocky River, Ohio and have it ready to be re-coated. We had to shot blast this and grind it in a multiple step process.

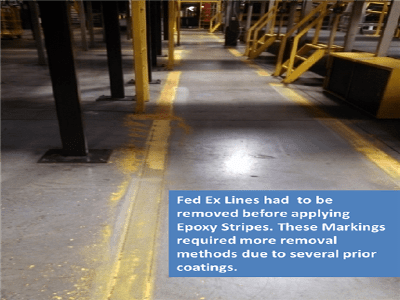

We shot blasted the lines off the concrete, but there are always options if the shot blasted finish is not what is desired at the end of the job. Some other options to consider are resealing where the markings were and re-polishing the concrete so as to bring back a smooth sheen on the floor. Shot blasting will very lightly break through the concrete so the pores are partially open.

Also, keep in mind that we have other methods of removal, but these methods require different timetables for completion and different equipment.

Have Questions About Our Industrial Blasting Services? Contact Us Today!

If your company is looking for concrete shot blasting contractors to perform functions such as removing coatings or preparing a surface for re-coating, you can count on ProMark Contracting’s team of professionals today. Contact us for more information!